Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

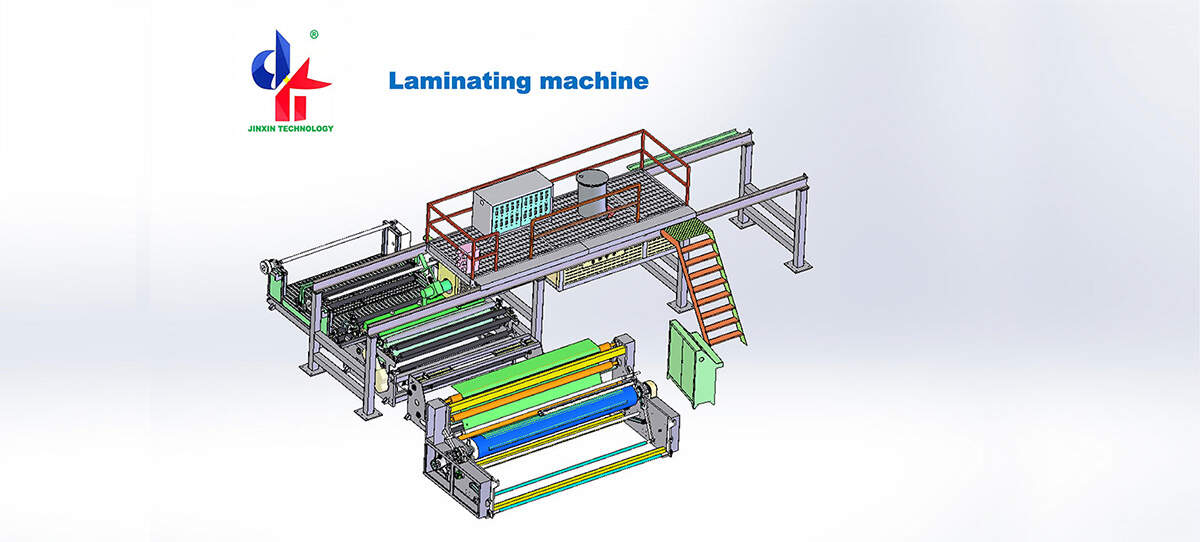

2022 Latest Digital Manual Dry Wet Textile Extrusion Coating Non-Woven Fabric Laminating Machine

This highly automated device has sophisticated construction, intuitive operation, little power consumption, and great productivity. To achieve consistent compounding, it uses twin extrusion-dies with compounded double-rollers. All of its completed products are high intensity and perform well in terms of look and application. This machine has an auto-correcting mechanism for automatically transmitting and guiding produced material. It is simple to use and has adjustable speed.

| Model | JX-laminating machine | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 12*10*3.5m | 12*12*3.5m | 12*16*4.5m |

| Mechanical Speed | 200m/min | 200m/min | 150m/min |

| Thickness | 0.01~0.1 mm | 0.01~0.1 mm | 0.01~0.1 mm |

| Daily Output | 2-3T/Day | 3-4.5T/Day | 4-5.5T/Day |

| Transformer Capacity | ≈80KVA | ≈120KVA | ≈180KVA |

| Power Consumption | 520°-650°Ton | 520°-650°Ton | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Product Description

This machine is highly automatic featured advanced workmanship, easy operation, low power consumption, and high efficiency. It adopts double extrusion-dies with compounded double-roller to make even compounding. Its finished products are all high intensity and have good performance both in application and appearance. This machine is equipped with an auto-correcting device for auto-guiding and sending processed material. It is speed-adjustable, easy to operate.

Product advantages

Key components are designed with advanced technology to meet customers' high-quality production needs.

The lamination section adopts a three-roll calender, which has the characteristics of uniform force, convenient operation, safety and reliability. The lamination section can be equipped with preheating rollers for preheating and drying the substrate. The laminating rollers, silicone rollers and pressing rollers are double-layer forced water-cooled circulation structures, with good cooling effect.

The rewinder uses dancing roller automatic tension control, flat push structure and pressure arm, double-station constant tension surface friction winding, pneumatic cross-cutting, and is equipped with edge trimming and edge blowing devices, product length measuring device to achieve uninterrupted roll change and smooth Roll winch (roll discharge device as option available)

For the lamination of oversized bag substrates, this machine adopts a fabric roll surface flattening braking device to ensure that the surface of the substrate is flat before lamination to improve product quality. The dual-station coiler adopts an automatic edge positioning controller for automatic positioning and positioning control of the substrate, and controls the surface tension of the base material by braking to realize the pneumatic connection of the cloth without stopping the roll change.

Increased production and reduced energy consumption. It is equipped with a turret device for tubular fabrics to achieve double-sided lamination of tubular fabrics. The extruder adopts a double-layer structure, and the plastic extrusion flow channel is designed by computer simulation. The extrusion capacity is large, the stirring effect is good, and the energy consumption is low.

Intelligent production, reducing labor. The whole machine can be equipped with man-machine interface and PLC programmable control to realize automatic functions such as program proportional linkage adjustment, fault interlocking, and interlocking.